Honing with Electromechanical Application

Flexibility in your production facility

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

Flexibility in your production facility

With our newly developed honing tools, we enable you to work with an electromechanical infeed process on machining, turning and milling centers (Machining Centers). The typical cross-hatch from honing is produced through the infeed application during processing.

With the specially developed Gehring tooling product line, you have many advantages in the honing process on machining centers.

We can offer you:

Each process is designed and managed by our specialists.

You have the possibility to machine a large diameter range without changing the tools with the fixed-sized friction reaming-honing tools. Wear compensation is performed via an automatic in- process adjustment system. The machining of the bore takes place by means of a single in and out retraction process.

We enable an optimal correction of the shape accuracy and the bore size even in the case of interrupted bores with the aid of our reaming-honing tools. Moreover, they are particularly suitable for milling centers, turning centers or general processing centers right up to the drilling machine application. The tools are custom adaptable by our specialists depending on the application and end case use.

We offer you:

For the processing on an electromechanical workpiece many different components are suitable.

Here is a selection of typical workpieces:

Your workpiece is missing? Contact us directly and ask abour our specialists for the suitable honing application.

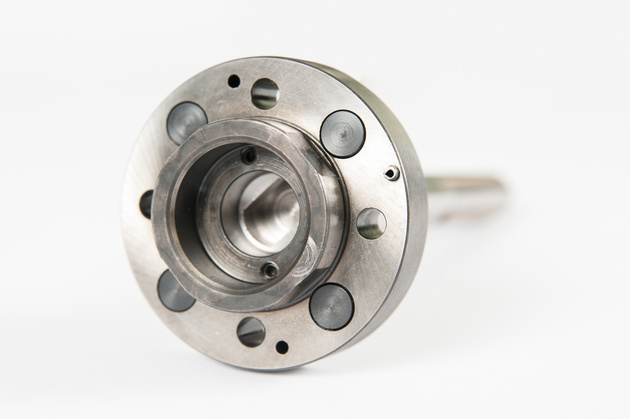

Our high-precision Gehring honing tools are individually designed for your requirements. We offer you honing tools with an adapted interface for your machining center, and the abrasives and the honing process from a single source.

In combination with Mapal TOOLTRONIC®, we offer a fully interchangeable tool axis, which serves a wide range of applications. It is flexible and can be adapted to part/component variations by simple programming. In conjunction with our honing tools with electromechanical infeed process, the highest quality and shortest processing times are achieved.

Our high-precision Gehring honing tools are individually designed for your requirements. We offer you honing tools with an adapted interface for your machining center, and the abrasives and the honing process from a single source.

In combination with Mapal TOOLTRONIC®, we offer a fully interchangeable tool axis, which serves a wide range of applications. It is flexible and can be adapted to part/component variations by simple programming. In conjunction with our honing tools with electromechanical infeed process, the highest quality and shortest processing times are achieved.

Are you looking for a solution for the Honing process on a Machining Center?

Here you will find the perfect solution. We have developed special tools for the honing processing on Maching Centers with our partner.

Utilize our knowledge in honing technology and abrasive manufacturing and bring these advantages to your production facility!

Please do not hesitate to get in contact with our specialists. They will gladly suppprt you in the choice of the correct tools and the correct processes to consider.