Laser structuring

Sublime microprofiles cause increased stiction

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

Sublime microprofiles cause increased stiction

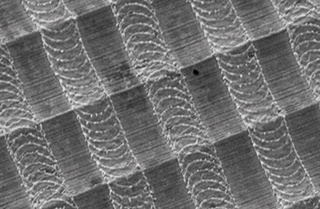

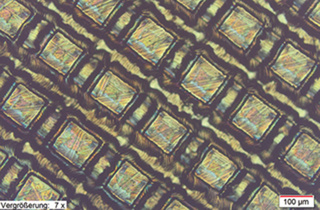

Laser structuring is increasingly used for roughening of surfaces. Superior micro profiles are created with this process, which cause the highest possible static friction to the counter body. The pulsed laser beam is focused on one point of the material surface whereby very high local intensities occur. Through the thermal machining process, the material is turned temporarily into a liquid phase. This leads to warpings which stand out of the surface.

The single profile peaks consist of melt fins which couple with its superior surface structures in its function as component in the surface of the counter body and create a high static friction.

A connecting rod bearing consists of the large connecting rod eye, the bearing shell and the crank pin of the crankshaft. Whereas the friction between the crank pin and the interior of the bearing shell is minimized, it must be maximized for the torsional reliability on the exterior. A frictional connection is therefore required between the connecting rod eye and bearing shell. After the precision machining (e.g. honing or precision boring) of the connecting rod eye, the machined surface is structured with a solid state laser. The torsional reliability of the mounted bearings to be achieved is thus the deciding quality parameter of laser structuring.

By roughening the technical surfaces with static friction function, a loss-free twist and/or restrained joint between two components is created. This connection fulfills the functional requirements and simplifies the constructive layout of the components.

Moreover, friction-increasing intermediate materials such as diamond foils are substituted and the costs for manufacturing are reduced further.

For the industrialization of laser structuring, plants which work with higher process reliability in modern production lines were developed. As sound source Q-switched laser with galvo scanner optic are used, which are normally found in labelling and marking of surfaces applications.

It is possible to arrange even more sound sources to achieve a further reduction of cycle times. The arrangement occurs depending on the machining task. During the structuring of bore sections, the rays fall diagonally in the bore. During the processing of direct accessible surfaces, the beam control can occur to the machining surface as usual.

Our new laser center systems are the right machines for the structure of con rods, cams, sprockets or other components. These offer a high process reliability in your production line.