By using our website, you agree that we make use of cookies to enhance your browsing experience with Gehring.

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

posted on September 18, 2015

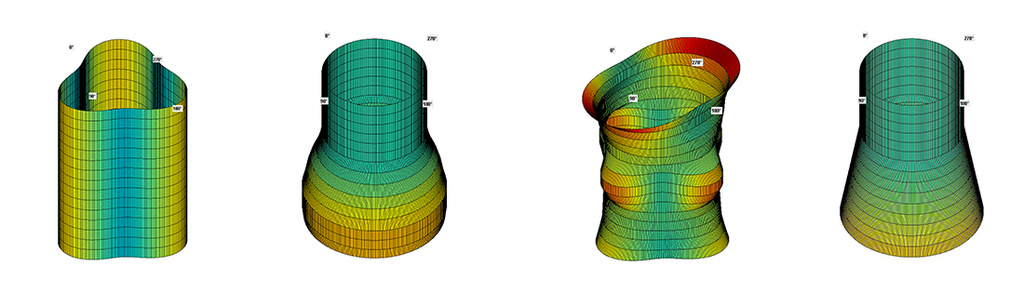

As a result of new quality criterion demands, the honing process is developed continuously. Thus, numerous process variables such as Form Honing, Plateau Honing, Ribhoning, or Helical Slide Honing emerged.

posted on September 16, 2015

The goal of position honing is to shorten the process chain of cylinder block production without a loss to the end quality. Position honing combines fine boring and honing into one step.

posted on September 16, 2015

Increasing component performance requires additonal quality improvements and the implementation of new quality parameters such as residual compressive stress. It further requires a continous adaption of manufacturing technology.

posted on September 16, 2015

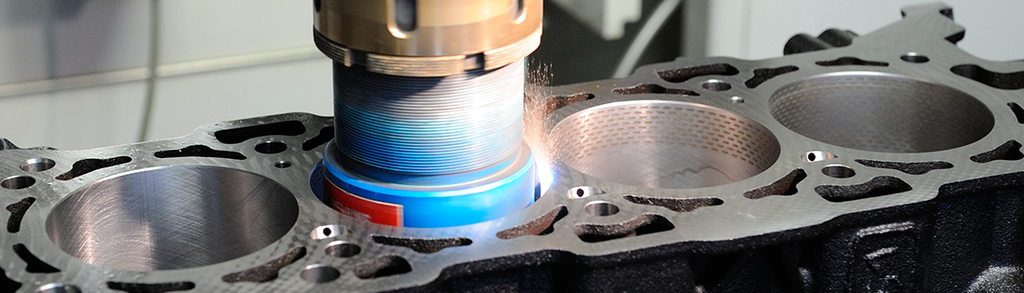

Rising customer expectations and future exhaust and emissions laws place extensive requirements on the oil and fuel consumption of gaseoline and diesel engines. The laser honing developed by Gehring has become an international standard.

posted on September 16, 2015

At present, the most important objective when developing internal combustion engines for vehicles is the reduction of fuel consumption and polluting emissions. The focus is currently on the CO2 value (g/km).