Defense and Aerospace

Functionally optimized surfaces for defense and aerospace applications- because precision matters

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

Functionally optimized surfaces for defense and aerospace applications- because precision matters

Gehring has been actively involved in serving the defense systems and aerospace industry on a global basis and provides a unique advanced technology that assists in meeting the challenges faced by today’s armed forces. These challenges place new and ever increasing demands on equipment, requiring innovative engineering and advanced manufacturing solutions.

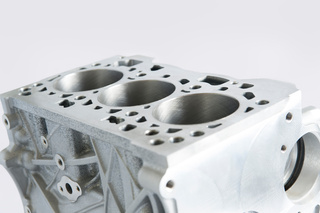

Gehring is able to deliver advanced honing technology solutions that assists greatly with performance and fuel economy, as well as low noise and exhaust emissions. Functionally optimized surfaces with improved tribological properties ensure lower oil consumption, emission improvements, reduced wear as well as lower fuel consumption. Gehring Honing Technologies serve government requirements for increased fuel efficiency, lower emissions, and reduced life cycle costs through increasing component life.

In the area of munition technology, honing has been proven to improve barrel and cannon performance - especially in spray-coated barrels - by producing more uniform and controlled bore geometry, size and surface finish.

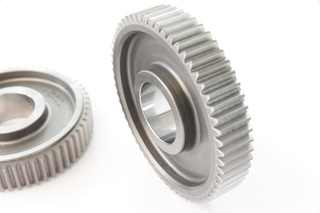

Cylinder Blocks, crankshaft bores, cylinder liners, connecting rods, gears, planetary gears, gun barrels, hyraulic components, tubes

Gehring is proud to be a Corporate Sustaining member of the AUSA and is a supporting partner in the Workshop for Warriors Program which is aimed at placing veterans into advanced manufacturing careers.

We are positioned to serve our customers on a global basis as we have manufacturing and service locations on four continents, all of whom operate under the "One Gehring" business model. This means we offer global solutions, application-relevant technologies, as well as full extensive service partnerships.

Since we have the flexability to serve our defense business from a separate ITAR compliant facility based in Livonia, Michigan, we assure confidential handling of your projects in house. This is of particular interest to companies who may have low volume applications for surface finishing, as we offer both prototype and contract honing, as well as a comprehensive process development consulting service from this site. Our CAGE code is 7A2Y7 and we are also approved under the Militarily Critical Technical Data Agreement Joint Certification Program.