Precision Honing Machines

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

Small bore diameters often place different demands on the production technology as large ones. Problems such as a less favorable length/diameter ratio of the bore and less available space have to be solved.

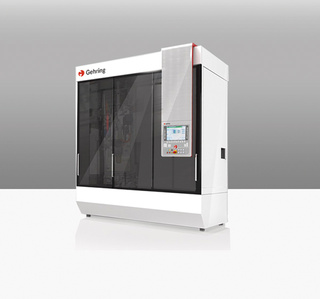

Due to the customer requirements we have continuously improved our lifehone machine. Market-proven functional modules have been included in a modular design - the result: a cost-efficient machine, short delivery times and functionally advanced components.

In order to meet our customers' requirements, we have continuously improved our lifehone machine. Construction modules were modified according to market requirements. Market-approved components were further optimized. We are proud to now present to you a cost-efficient machine with short delivery times and functionally advanced components.

Whether constructed as a multi-spindle transfer solution for mass production, or as single-spindle design for small batches - highly accurate parts with honing diameters up to 90 mm can be processed optimally with the appropriate machine. Characterized by simple use and high performance, you will find the right solution for your requirements and process conditions.

Easy operation and optimal configuration options

We select the appropriate honing unit based on both the range of products that are machined and individual customer-related requirements.

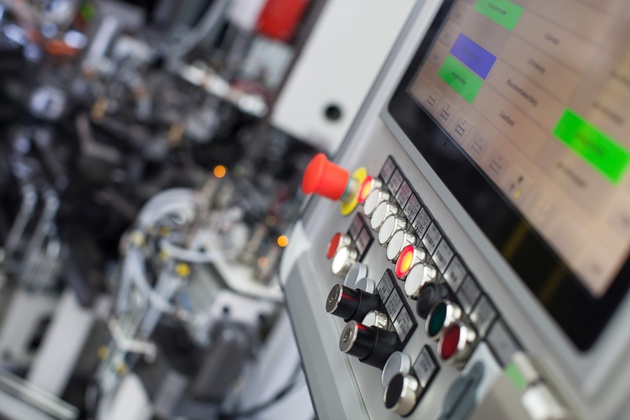

The Gehring honing control allows for precision controlled stroke speeds and reversal precisions. For the stroke drive, you can choose between a ball screw or a linear motor.

The user-friendly and clearly structured interface of the Gehring operator panel (GOP) as well as the program assistant simplifies machine operation significantly. After entering relevant data on components, material and tool, process and stock removal can be defined to start the honing process straight away once the respective tools are positioned. Stroke position and all relevant parameter for machining are automatically calculated.

The bore diameter and the conicity are calculated by the pneumatic gauging system and graphically displayed on the honing control display. In-process as well as pre- and post-gauging systems can be installed upon request. It is possible to integrate a brushing process to deburr slight burrs at the edges of holes or cross holes produced during the honing process. We further give you the option to integrate a centrifugal application or blowoff-station to remove the coolant from the respective workpieces.

Your benefits:

The single spindle version of the Lifehone series is impressive with its compact design and small footprint. Depending on the machining task and the batch size, this type of machine can be equipped with a fixed or rotary table and up to 4 stations.

| Technical Data | 1-Spindle Honing Center |

|---|---|

| Required space (WxDxH) | 1400 x 2150 x 3500 mm |

| Weight | 3500 kg |

| Application Samples | injection pump components, housing, hydraulic components |

Subject to technical changes and variations in design and configuration!

Compared to the single spindle honing center, this option is 60 cm wider. The two spindles allow for a two stage honing process, and therefore shorter honing times and honing of more material. Rotary tables with maximum of 8 stations offer place for gauging operations or brushing operations.

| Technical Data | 2-Spindle Honing Center |

|---|---|

| Required space (WxDxH) | 2000 x 2900 x 3500 mm |

| Weight | 3650 kg |

| Application Samples | injection pump components, housing, hydraulic components |

Subject to technical changes and variations in design and configuration!

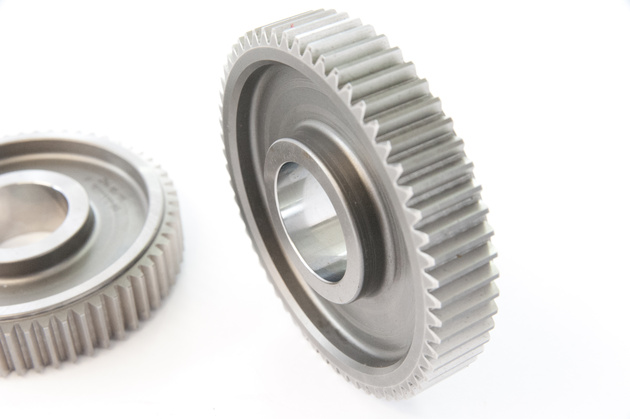

This machine is especially designed for the needs of machining of transmission parts, for examples gears. The integrated gripper transport offers the possibility to cycle gears with different diameters. Furthermore, the user only needs one fixture below the two spindles.

| Technische Daten | Honing Center for Gears |

|---|---|

| Required space (WxDxH) | 2000 x 2500 x 3500 mm |

| Weight | 3800 kg |

| Application Samples | especially designed for gear wheels |

Subject to technical changes and variations in design and configuration!

Alternatively equipped with a six or eight sided inner column, you can fix up to 7 honing spindles. With this feature, we can assure short cycle times and multistep processes. Pre and post gauging stations are fixed on the opposite side to optimize the interior space of the machine in the best way possible.

| Technical Data | Honing Center with inner column |

|---|---|

| Required space (WxDxH) | 2100 x 2400 x 3600 |

| Weight | 3500 kg |

| Application Samples | gear wheel, pinion gear, injection pump components, housing, hydraulic components |

Subject to technical changes and variations in design and configuration!

Our three-spindle lifehone hones the workpieces horizontally. The machine is loaded via a handling system from the pallet. In general, the number of workpieces per pallet is between 5 to 10 pinion gears. The advantage of this pallet method is the shortened processing time per workpiece.

| Technical Data | Horizontal Honing Center for Pinion Gears |

|---|---|

| Required space (WxDxH) | 400 x 1800 x 2900 mm |

| Weight | 3650 kg |

| Application Samples | especially designed for pinion gears |

Subject to technical changes and variations in design and configuration!

The transfer design of the lifehone series is usually recommended for solutions with four or more spindles. Depending upon the desired cycle times and honing process, the machine is designed with the correct number of spindles. This design also makes sense when different bore diameters must be processed on one workpiece.

| Technische Daten | Transfer Honing Machines |

|---|---|

| Required space (WxDxH) | 2300 x 3450 x 2400 mm |

| Weight | 3800 kg |

| Application Samples | connecting rod |

Subject to technical changes and variations in design and configuration!

We select the appropriate honing unit based on workpiece design and required speed dynamics.

| Technical Data | L 200 | L 630 |

|---|---|---|

| Stroke Length | 200 mm | 600 mm |

| Diameter | 0,6 - 12 mm | 3 - 90 mm |

| Spindle Drive | Servo Motor | Servo Motor |

| RPM, max | 6000 1/min | 4500 1/min |

| Torque | 15 Nm | 60 Nm |

| Stroke Drive | Linear Drive | Ball Screw |

| Stroke Speed, max | 60 | 40 |

| Stroke Acceleration, max | 25 | 25 |

Subject to technical changes and variations in design and configuration!

The super finishing of high-precision components depends on the perfect coordination of factors essential to the honing process: honing tool, abrasives, fixtures, feeding and gauging systems. All of these elements must be perfectly matched to one another to achieve an optimal result. We supply you with the complete package from the abrasives to the machine, so that you always receive the perfect solution for your application.

The single-stone L series tooling system is especially designed for honing high-precision bores with a diameter range of 3–15 mm. The tool connection and base are assembled by means of “thermal shrinkage”. This joint is characterized by high concentric accuracy (≤ 5 μm) as well as the capability to transfer high torque and axial forces.

In addtion to tools and abrasives, we offer various automation concepts - Automatic loading or unloading with robots or gantry.