USA

- International

- EN

- DE

- USA

- EN

- China

- 中国

- EN

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

The new generation of smarthone machines particularly considers the needs of contract manufacturers in job shop production and prototyping, meeting highest requirements in regard to flexibility and efficiency. From manual honing in single piece production up to fully automated operations, all suitable operating modes are available. In addition to short set up and machining times, importance was laid on user-friendliness and work safety.

Additional Brochures in the Download-Center

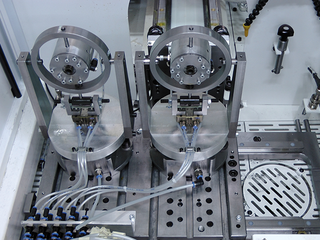

All necessary functions, such as the coolant conditioning and superfine filtration, are integrated into a compact floor space of only 1.6 m2. The costoptimized horizontal honing system is designed for the production of most diverse batches and product ranges. Precision work pieces with diameters of 0.8 - 45 mm and honing lengths of up to 200 mm can be produced very efficiently within short cycle times. Stroke speeds of up to 60 m/min and accelerations of up to 4g are achieved.

The machine is designed for honing the most diverse batches and product ranges. Precision components with diameters of 0.8 - 45 mm and honing lengths of up to 200 mm can be produced. The highly dynamic linear drive system allows for stroke speeds of up to 60 m/min and accelerations of up to 40 m/s². In addition, the patented electro mechanical expansion with force sensor offers force and stroke controlled honing. High stock removal and machining qualities as well as short cycle times can easily be achieved.

If needed, the standard design can be gradually extended by relevant options resulting in an optimal cost-benefit-effect for the operator due to the high degree of standardization. Upgrading options could be in-process gauging with feedback control or an internal coolant supply though the honing tool for further process improvement. The implementation of a cost-optimized ream honing process may also be a meaningful alternative for corresponding applications.

Thanks to "Job Manager" and configured interfaces, setting up or retooling the machine is possible within the shortest timeframe. This also applies to changing and controlling various types of fixtures, tools and functions. The intuitive operator interface minimizes the preparation times and training processes for additional operators. Additionally, short changeover times and a high degree of reproducibility are ensured by the specially adapted and investment-friendly tool program.

Precision and longevity are the hallmarks of our tooling systems, ensuring cost effectiveness, optimized surfaces and the best possible bore geometries. Take advantage of the Gehring tooling system especially adapted to your machine.

With the smarthone, you benefit from Gehring's 90 years experience with the realization of high-performance honing technology for customers from all over the world.

In the interest of our customers we always find new and innovative ways for optimal support in future tasks. From now on, our business strategy also allows small and medium-sized contract manufacturers to benefit from the know-how of the market leader.

| Technical Data | honing machine |

|---|---|

| Stroke length | 200 mm |

| Diameter | 0,8 - 45 mm |

| Spindle drive | servo motor |

| Speed, max. | 4500 l/min |

| Torque | 31 Nm |

| Stroke drive | linear motor |

| Stroke speed, max. | 60 m/min |

| Stroke accelration, max. | 40 m/s² |

| Space requirements (WxWxH) | 880 mm x 2000 mm x 1600 mm |

| Weight | 2500 kg |

| Noise emission | <72 dB |

| Honing controller | Gehring GCU 2.3 |