What is honing?

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

As a result of new quality criterion demands, the honing process is developed continuously. Thus, numerous process variables such as Form Honing, Plateau Honing, Ribhoning, or Helical Slide Honing emerged. We therefore see our customers as partner with regard to the development of innovative and progressive process ideas.

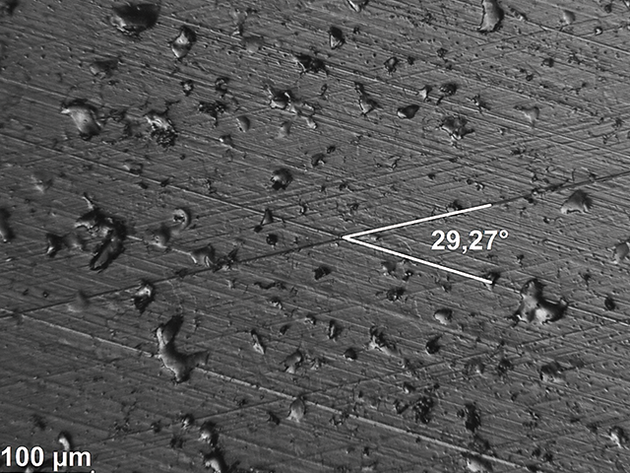

Honing is a machining process that produces functional surface finish of bores. In addition to the dimensional and geometrical accuracies achieved, the topographic form of the roughness of the surface is of increasing importance. This can either be a smooth surface or a rough topography with defined oil pockets. The structure of the cross hatch grooves has a crucial tribological significance. The function of honed surfaces are always in tolerance, gliding or sealing and guiding. From this, we can see the end use applications of honing. Typical parts that are subjected to the honing processs are pistons of internal combustion engines, liners, crankshafts made of cast iron, aluminum or iron alloys with different microstructures.

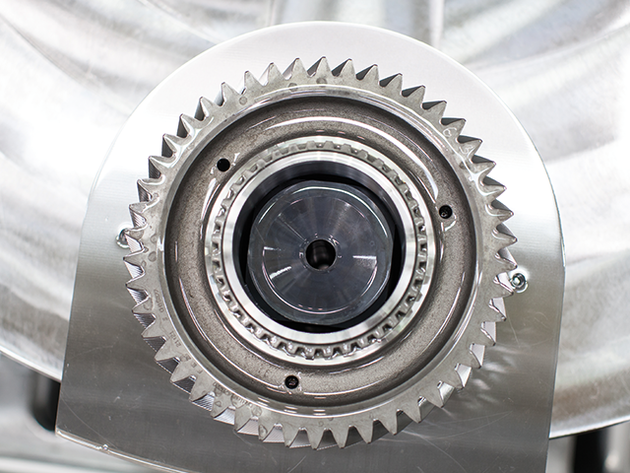

There are particularly high geometric requirements placed on valve bores in hydraulic, pneumatic and fuel injection systems. Gears, connecting rods, hydraulic cylinders, suspension cylinders and ceramic components are also precision parts that are honed in different batch sizes. We can offer honing machines with different machining areas (bore diameter, honing length) and degrees of automation. Bores with diameters between 0.8 mm and 200mm and lengths up to 24 meters can be processed on Gehring honing machines. Common to all configurations is the honing angle, under which the honed grooves intersect (cross hatch). The achievable accuracies with respect to dimensional tolerances, cylindrical shape and roughness meet the function requirements of energy efficient aggregate.

Here you will find some typical workpieces for the honing process as well as a short film about our honing process.

This is only a small excerpt of the parts that can be machined. If you have a question or would like to know if we can process your work piece please contact us!

An essential feature of the honing process is the process of kinematics. It is executed by the tool and includes the lifting, turning and feed motion. These kinematics give this process the typical honing angle. The feed movement causes a radial spreading of the tool, whereby the abrasive makes contact with the bore walls. This is created through a electro mechanical feed system whereby the feed force can be controlled in adjustable limits.

In addition to kinematics, coaxiality is an essential feature of the honing process. As mentioned, the honing stones can be moved against the bore wall by the radial feed. Through the feed motion, the tool is centered in the bore. Bore axis and tool axis are identical. This allows for sufficient degrees of freedom with respect to the tool assembly. For this purpose, the tool is double hinged to the honing spindle. This arrangement allows the tool to adjust the position and angle of the bore. Locational accuracy can not be corrected by honing. However, there are exceptions -as in the case of position honing - which are carried out with a rigid tool.

The Diato honing stones which are also a product of the Gehring Group, have abrasives made from synthetic diamond or cubic boron nitride (cBN). These abrasive crystals are embedded in a hard metallic matrix. The grit size is then responsible for the stock removal of the material.

For detailed information about our cutting materials please click here.