Laser Honing

Reduction of friction and wear by combining honing and laser structuring

You are using a very outdated browser. To make full use of our website, we recommend that you update your browser to the newest version.

Reduction of friction and wear by combining honing and laser structuring

Rising customer expectations and future exhaust and emissions laws place extensive requirements on the oil and fuel consumption of gaseoline and diesel engines. The laser honing developed by Gehring has become an international standard. For both diesel and gaseoline engines, the laser structuring of the cylinder is currently applied in the range of the upper piston reversal point.

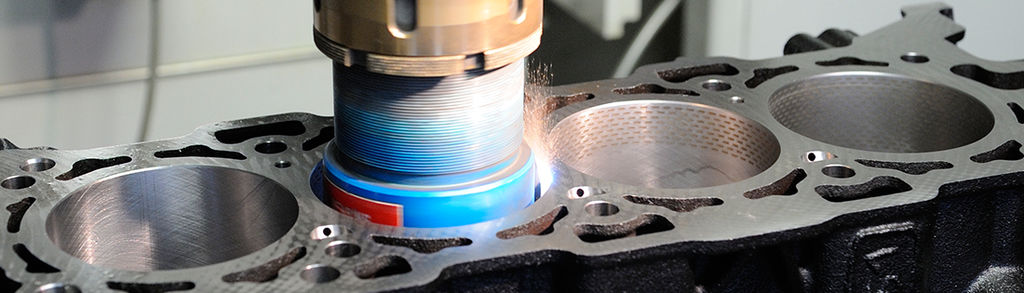

The combination of laser structuring and honing of cylinder bore surfaces is known as laser honing.

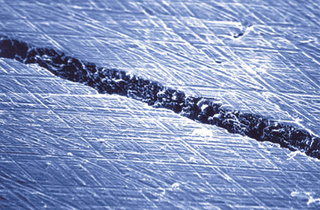

The combined honing and laser structuring of cylinder bore surfaces is considered laser honing. During this process, the engine block first undergoes the conventional rough and intermediate honing step in order to achieve the desired base profile for the laser structuring. Microscopic pockets, the engine-specific laser structure, are created into the cylinder bore surface by means of a laser beam. The subsequent final steps, deburring and finish honing, remove the melt protrusions arising from the laser processing to create an extremely fine surface.

In principle, the frictional forces in the tribological system consiting of piston ring and cylinder bore are to be reduced.

As a contribution to the future viability of internal combustion engines, laser honing provides an opportunity to improve exhaust emissions so that the future exhaust limits such as Euro 5 and Euro 6 are easier to achieve.

The advantages of laser honing have been proven in dynamometer and fleet tests as well as in numerous series applications. Due to the smooth cylinder bore surface and the superimposed micropocket structure the tribological system of piston ring - cylinder bore offers numerous customer advantages: